Occupation Spotlight: Molder in a Foundry

Frank Petrasek, my 2x great-grandfather worked in a foundry

Born in “Bohemia” in 1859, Frank Petrasek came to America as a very young boy. (As boundaries changed throughout his lifetime, Bohemia was referred to as Austria and later as Czechoslovakia in various documents. Today it is known as the Czech Republic.) He was the first born of Joseph and Johanna; and his mother was with child when they made the journey. The baby boy was born an American citizen before the family reached their final destination! They came to America via the Port of New Orleans and took a steam boat up the Mississippi River to La Crosse, Wisconsin, first appearing on the United States census in 1870.

Frank’s father and brother had “laborers” listed as their occupations on censuses over the years, but starting in 1880 when Frank was 20 and still living in La Crosse, he was noted as working in a foundry. Frank didn’t complete school beyond 6th grade, so it is probable that he started working in a foundry from a much younger age. Sometime between 1923-1924, at the age of 64 he retired, having worked all that time -- over 50 years -- in a foundry, mostly as a molder.

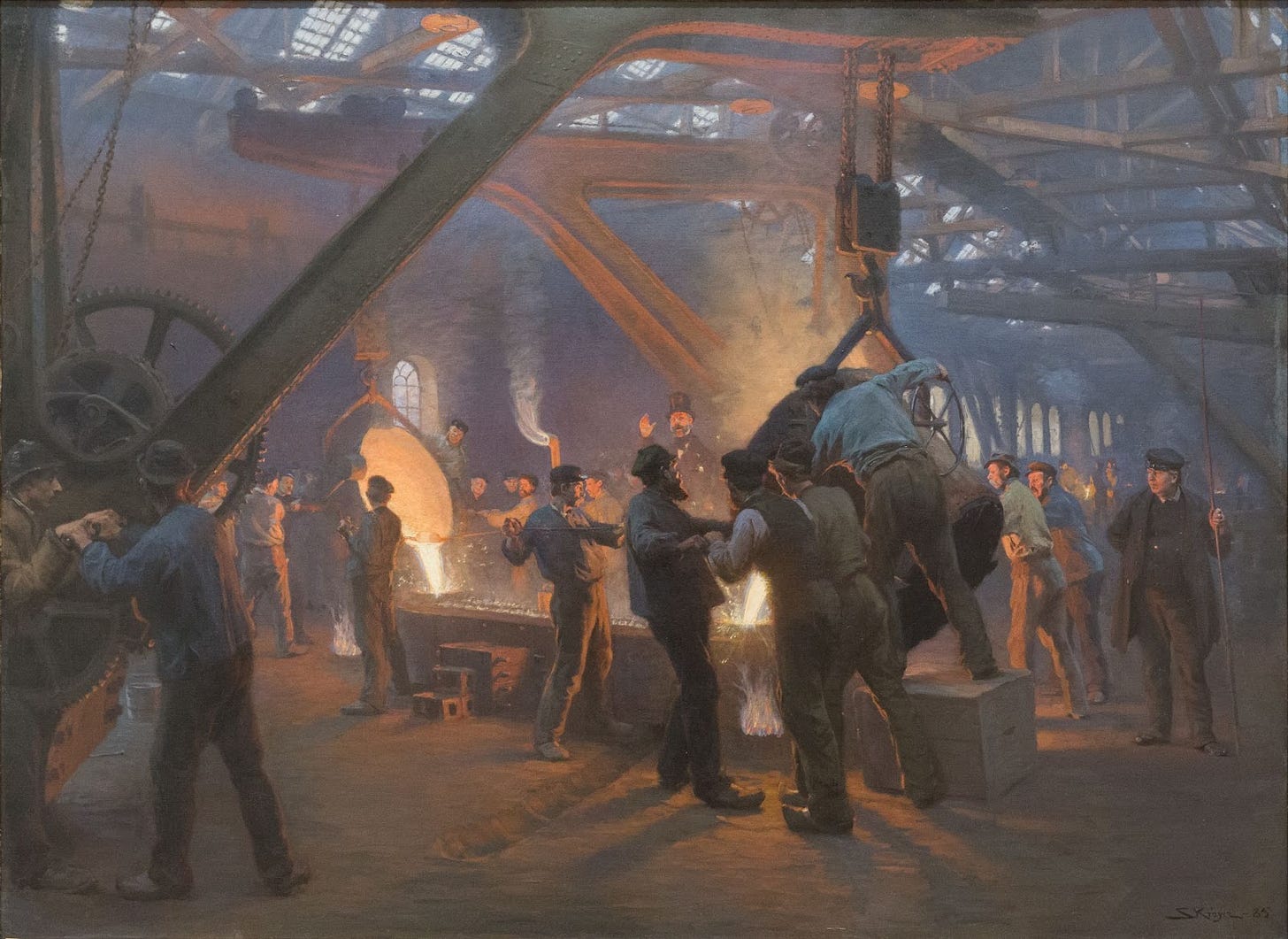

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing it from the mold after it has cooled and solidified. A molder was a highly skilled job creating molds in casting sand. A description of a molder’s job from a 1913 issue of The American Economic Review states:

The molder was supreme. Thorough and dirty, molding was a highly skilled trade requiring considerable technical proficiency, and in which the processes, many of them [seemingly] simple, demanded long training and experience. A man had to know how to treat his sand so as to get a mixture just suitable for withstanding the heat and force of the molten metal. He had to set the cores accurately and ram the sand around the pattern so as to get a true and substantial matrix. Drawing the pattern so as not to break the mold was a very delicate process and any resulting imperfection had to be carefully patched. The mold had to be properly vented to allow for the escape of gas arising when the metal was poured. The iron, melted to white heat in the cupola, was poured by the molder who carried his own ladle from furnace to mold. In the process, if the mold was not properly made, an explosion might occur or pieces of sand might break loose and run in with the iron, or the metal might not flow freely and evenly, thus leaving unjoined portions; or it might shrink internally, causing holes and spongy places. In any of these circumstances, the casting was imperfect; his time and the material had been wasted.

Casting melted metal started about 4,000 years ago and of course modern versions exist today; but starting in the 1860’s, when railroads were moving west across the continent, Minnesota foundries played an essential role.

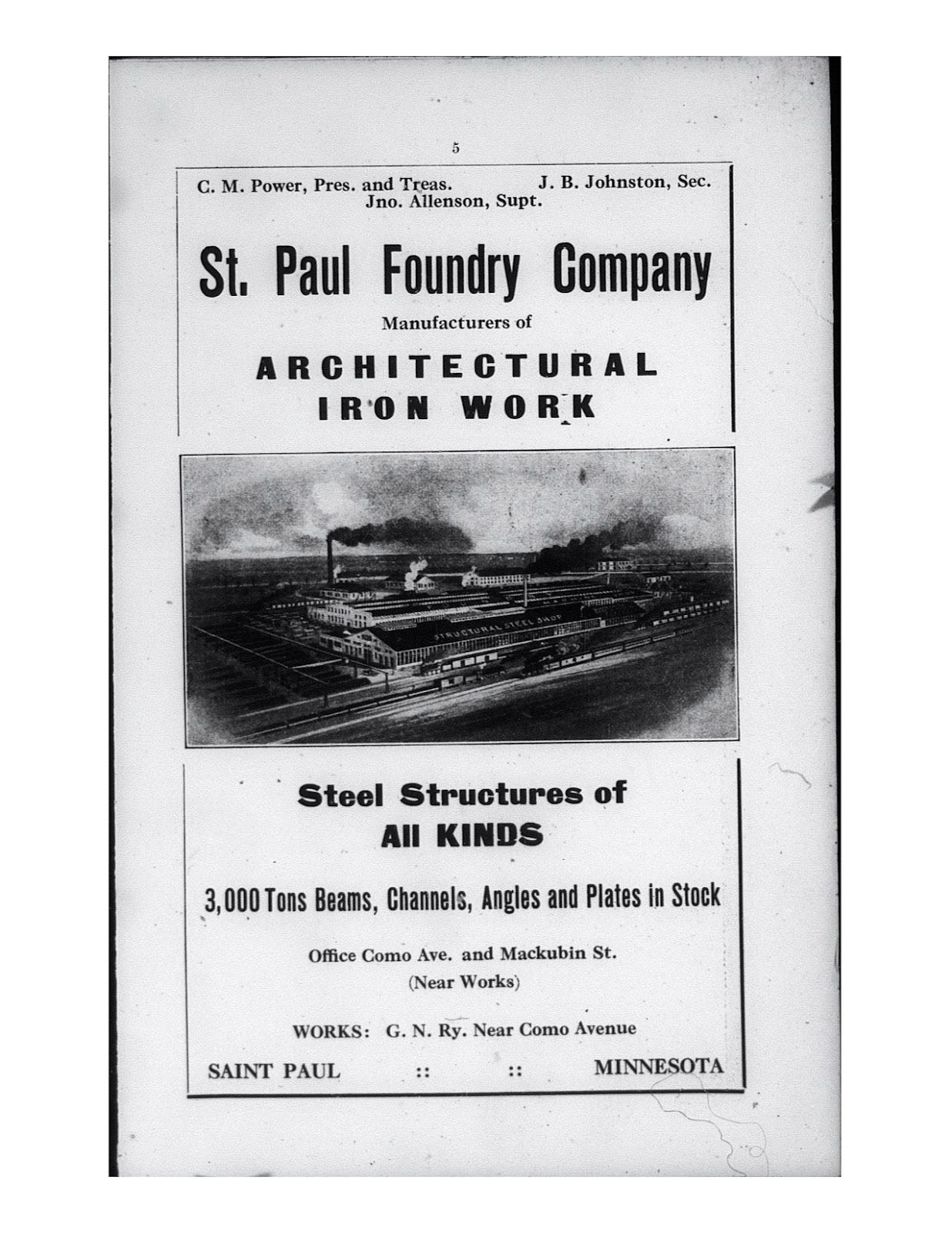

Shortly after he married and for the remainder of his career, Frank worked at the St. Paul Foundry in St. Paul, Minnesota which started in 1863 and was originally launched as a supplier for the Great Northern and Northern Pacific railroads. Throughout Frank’s time with the company, ownership changed hands a few times, but a railroad was always a major stockholder.

The St. Paul Foundry was a bit different from others in the area because it specialized in brass. In the early days, demand from the railroad was a key part of the business. By 1900 electrical generation and firefighting equipment drove its growth. During the world wars they supplied the allied efforts. Saint Paul Foundry continues to operate today as Minnesota’s oldest manufacturer specializing in quality brass, bronze and aluminum sand castings.

Sources:

“So Your Ancestor Worked in the Iron Industry?”, accessed September 22, 2023. https://www.culturenlmuseums.co.uk/story/so-your-ancestor-worked-in-the-iron-industry/

“About Metalcasting” American Foundry Society, accessed September 22, 2023. https://www.afsinc.org/about-metalcasting

Foundry. (21 May 2023). In Wikipedia. https://en.wikipedia.org/wiki/Foundry

“St. Paul Foundry” by Jane McClure. Saint Paul Historical. Accessed September 22, 2023. https://saintpaulhistorical.com/items/show/60#:~:text=The%20foundry%20was%20started%20in,for%20thousands%20of%20area%20residents.

“St. Paul Foundry - A History of the Oldest Manufacturer In Minnesota” St. Paul Foundry. Accessed September 22, 2023. https://stpaulfoundry.com/About/history.aspx

“St. Paul Foundry Celebrates 150th Anniversary” (20 December 2019). In PR Newswire. https://www.prnewswire.com/news-releases/st-paul-foundry-celebrates-150th-anniversary-300978239.html

Hoagland, H. E. (1913). The Rise of the Iron Molders’ International Union: A Study in American Trade Unionism. The American Economic Review, 3(2), 296–313. http://www.jstor.org/stable/1827955

Most say working long hours is crazy, but you don’t notice while you are doing it. I never worked that long but I remember working long hours. Sometimes we think we have it tough but nothing like other people had it then. It’s hard to believe !

Hard worker! That must be where Dad gets it from!